Automotive EV-olution; A family auto repair business stays current in the changing world of automobile technology

Watson’s is “in the people business, where we happen to fix cars.”

Bob Watson is no stranger to changes in car design. After all, he has been in the auto repair business his entire working life. He’s the owner of a small, family-run auto repair shop where community members meet and linger to “shoot the breeze” over the counter. Bob greets his customers like old friends, and many of them have become exactly that.

In high school Bob distinguished himself as a math wizard. His exceptional mechanical aptitude pointed him in the direction of technical college where he earned an Auto Mechanics Associate Degree, while holding down two jobs to pay his way. After graduation he had no trouble finding employment and worked his way through various auto dealerships in the region, rising swiftly through the ranks. In 1983 he took the job as manager of what used to be known as Huggett’s Auto in East Thetford, and in 1995 purchased the business side of it, renaming it Watson’s. The garage building itself remains in the steady hands of owner Bonnie Avery.

Michael Watson, Bob’s oldest son, grew up around the family business. He’s always been an energetic worker, sweeping the floors and helping out at Watson’s Auto to work his way upward. After high school he immersed himself seriously in auto maintenance and obtained his Associates Degree in Applied Science from Vermont Technical College.

Michael’s brother, Jason, followed a similar path, being a presence at the garage from age eight, when he helped out with oil changes, then working there from age 15. After completing his studies in Automotive Technology at Riverbend Career and Technical Center, he went straight back to work at Watson’s.

Kevin, Bob’s brother, is also a mainstay at the garage, and Bob’s wife, Nancy, handled the accounts and was, according to Jason, the “real boss” around the place up until her retirement a few years ago.

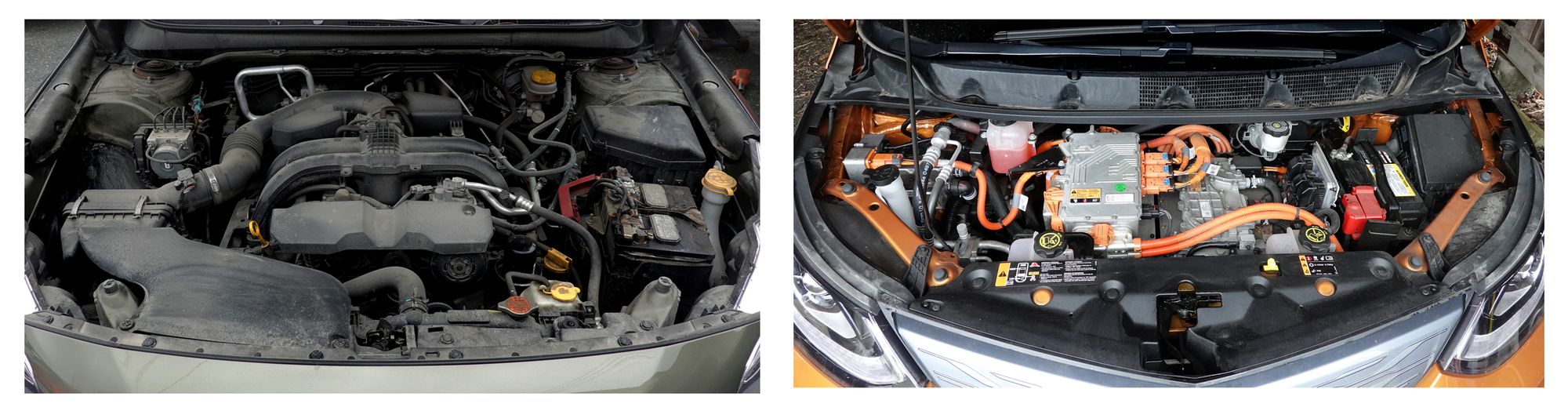

Major changes in automobile engineering have taken place over the course of Bob’s career.

He saw carburetors disappear in the early 1990s, along with engine chokes that adjusted the fuel mixture for cold starting. In their place, injectors now squirt fuel directly into the engine valves at phenomenal pressures of up to 2500 psi, producing an instantaneous burn. The familiar condenser and points that regulated the ignition spark gave way to electronic ignition and ignition control modules. Even distributors that send power to the spark plugs in sequence are being superseded by direct-mounted coils at each spark plug. Their firing is orchestrated by the car’s computer. With computers came advances like variable valve timing and stop-start engines that achieve better fuel efficiency. These systems have fewer serviceable parts and require less maintenance compared to “old-style” engines that wore out components on a regular basis. For instance, points, condensers and standard spark plugs lasted about 15,000 miles, whereas a modern electronic ignition system with iridium-tipped spark plugs can run trouble-free for 90,000 miles.

Both new technology and the way cars are now manufactured are changing the face of auto repair. Garages don’t generally rebuild systems like starter motors and brake calipers any more. It’s become a case of “remove and replace.” Box up the old components and return them to be re-manufactured at source.

Bob reminisced that at one time a good mechanic needed two things, the attitude that the job had to be done right, and just as important, a good ear. There used to be no technology for fine-tuning certain adjustments or diagnosing some problems. It was all done through feel and sound. A few decades later, auto mechanics have morphed into technicians wielding electronic scanners, laptop computers, and lab scopes. Repair manuals have given way to internet searches. An effective auto technician is computer-savvy and has a good electronic mind, but doesn’t know as much as his old-time counterpart.

Michael noted that car manufacturers don’t make life easy either. Each one has its own style of computer with its unique system logic, and the same auto parts are named differently by each company. A technician has to keep constantly well-informed in order to navigate online databases to look up protocols and components. Technological advancement seems to proceed faster all the time. To stay abreast of the industry, Michael has already taken six classes this year, ranging in length from 2-1/2 to 4 hours. He expects to take 10 to 15 classes total in 2021, many of them electro-mechanical.

A modern car operates with the help of at least 15 control modules. These mini-computers network together to sense faults in the car itself, as well as system faults in the network. Even something that seems simple, like rolling down a window, involves a main switch or main module that communicates with the car’s security system, its restraint system, and the interior lighting.

And there’s a catch to all this. If a module has to be replaced, only the dealer can re-program the replacement to integrate it with the car’s network. Dealers charge $200 each time they re-program, and they don’t give re-programming privileges to private garages. If Watson’s cared to acquire the ability to re-program, they would have to buy a $10,000 computer for each of the different car manufacturers. Luckily, Snap-On Tools offers a work-around, as it has contracted with at least some manufacturers. Technicians at Watson’s can hook up a Snap-On device that puts the module through the re-program cycle. But competition from big dealerships, overall loss of independence, and changing technology is forcing some small garages out of business.

Electric vehicles (EVs) are a hot topic of discussion at Watson’s. Jason observed that his kids, and youth in general, embrace the change to EVs. There’s more resistance among older generations, a questioning where all this is leading and whether jobs in oil and other industries will be lost in the technological shuffle. Presently the distance range of electric cars, limited by how much charge the battery holds, is a problem to some. You can’t just hop in and drive carefree to California. But EV technology has already changed in the past five years and will continue as automakers add more EVs to their lineup. In another two years Jason expects to see a new generation of EVs with increased range that could make first-generation EVs seem rather inadequate. It is unknown whether EV technology will translate to heavy duty equipment like dump trucks and bulldozers, though electric buses are in the works. In the end, the biggest hurdle is pushback from consumers and how government builds up the supporting infrastructure.

So far, hybrid vehicles and electric cars have not affected business at Watson’s. Many clients who get service there drive hybrids. Bob remembers the trailblazing Honda Insight, for which parts are no longer available, and the early Prius with rocker panels that would rust out. Hybrids brought the innovation of the automobile generator and regenerative braking. Mechanically, electric cars have fewer moving parts and do not require much in the way of service. Jason might not encourage his kids to embark on a career at Watson’s without considering the EV impact on auto maintenance. However, cars will still have wheels, a suspension, and brakes that will need attention. It is the unit that drives the car that has changed, be it a gas powered engine, a hybrid motor, or an electric motor. The bottom line is, garages have to keep up with the technology.

And that is what’s happening at Watson's. They all participate in ongoing learning to stay abreast of technological advances that frequently result in cleaner, more efficient cars. They are switching to recharging car air conditioners with a new “freon” R1234 that doesn’t deplete the ozone layer or have a high global warming potential (HGWP). They are marketing Nokian tires made entirely of canola oil because regular tires incorporate two harmful oils that end up in the environment. Bob himself became intrigued and then enamored with electric cars, so much so that Watson's is now the proud owner of a company EV shuttle. He’s also considering having an EV charger for community use. While continuous evolution seems to be their motto, Bob says another secret ingredient is key to success: They are not really in the auto repair business! Watson’s is “in the people business, where we happen to fix cars.”